‘T’ SUSPENSION TOOL

Installation

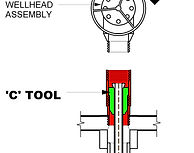

‘C’ SUSPENSION TOOL

Installation

WELL MAINTENANCE PROCEDURES

-

Unseat bottom hole pump and kill well down tubing.

-

Remove the wellhead assembly at the predetermined point.

-

Install the WST rod suspension tool.

-

Install a high pressure wellhead assembly.

-

Record shut in tubing and casing pressures.

-

Perform procedure by circulating down the tubing while monitoring the backside annulus pressure to determine how the well is responding during the operation.

-

Flush well as required.

-

Remove WST tool & high pressure wellhead assembly.

-

Re-install polished rod/stuffing box and re-seat bottom hole pump.

-

Resume production.

<-- T Tool installed

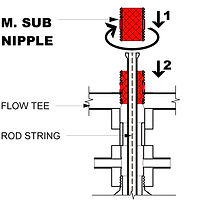

TO SUSPEND

-

Raise polished rod to unseat bottom hole pump and kill well.

-

Unseat stuffing box, expose sucker rod, break connection and lay down polish rod and stuffing box. .

-

Strip over (slide on) marker sub nipple over exposed sucker rod and attach to tubing string.

<-- C Tool installed

4. Install the WST 'C' tool, landing into the top of the

maker sub nipple.

5. Strip over the marker sub collar.

6. Install a wellhead assembly.

SERVICE RIG PROCEDURES

PREPARING FOR THE INSTALLATION

-

Kill well down tubing.

-

Install MS landing sub on top of flow tee.

-

Install sucker rod table system.

-

Perform normal operations

'T' TOOL INSTALL

-

Ensure that the well is dead.

-

Strip off and remove rod table.

-

Install WST ‘T’ Tool.

-

Install TIW valve.

-

Well secured.

Reverse the procedure to re-commence operations

TO RE-ACTIVATE WHEN USING A 'C' TOOL

-

Kill well as required.

-

Remove wellhead assembly.

-

Remove WST rod suspension tool.

-

Re-install polished rod / stuffing box.

-

Re-seat bottom hole pump.

-

Resume production.

'T' Tool Installation without Audio

'C' Tool Installation with Audio